welding pipe

Welding pipe also called welded steel pipe is made of steel plate or steel strip through crimp forming thus welding. The length is 6 meters. Welding pipe production technology is simple, high production efficiency, variety specifications, less equipments investment while the strength is generally lower than seamless pipe.

With rapid development of high quality strip steel rolling production and improvement of welding and testing technology, welded pipe is gradually taking the place of seamless steel pipe in the most field. Due to increasing welded quality, the specifications of welded steel pipe are variety. Small diameter welding pipe uses straight seam welding, large diameter welded pipe uses spiral welding.

Common material for welding pipe: ASTM A36, 16Mn, 20#, Q345, L245, L290, X42, X46, X60, X80, 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb etc.

Low pressure fluid conveying welding pipe: it is used for transporting oil, water, natural gas and heating water or steam. Represent material: ASTM A36

Mine fluid conveying welding pipe: it is mainly used for mine pressure, drainage, wind shaft gas with straight seam welding pipe. Represent material: ASTM A36

Stainless welding pipe for mechanical: it is mainly applied for machinery, automobile, bicycle, furniture, hotel and restaurant decoration and other mechanical parts and components. Represent material: 0Cr13、1Cr17、00Cr19Ni11、1Cr18Ni9、0Cr18Ni11Nb etc.

Stainless welding pipe for fluid conveying: it is mainly use for conveying low pressure corrosive medium. Represent material: 0Cr13、0Cr19Ni9、00Cr19Ni11、00Cr17、0Cr18Ni11Nb、0017Cr17Ni14Mo2.

How is the Production Process of Welding Pipe?

The production technology of straight seam welded steel pipe is simple, high production efficiency, low cost and rapid development. The strength of spiral welding pipe is generally higher than straight seam welded steel pipe. Compared with the same length of straight seam pipe, welding seam increases by 30-100% and the production speed is much lower.

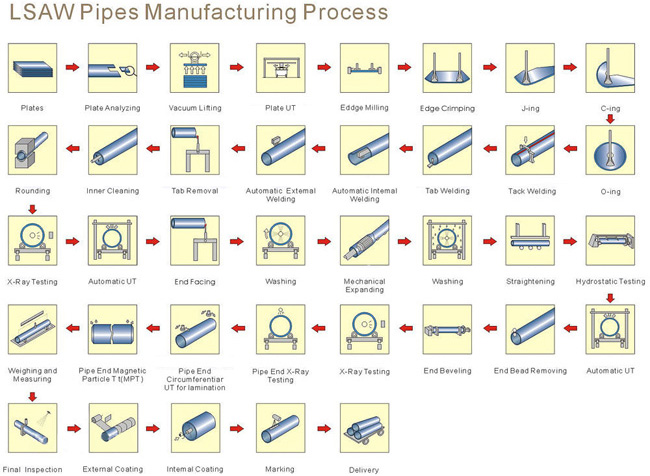

Welding Pipe-LSAW Pipes Manufacturing Flow:

The classification of welding pipes: common welding pipe, galvanized welding pipe, wire casing, transformer pipe, special pipe, Spiral welding pipe etc.

Common welding pipe: it is used to convey low pressure fluid and is made of ASTM A36 steel or other mild steel easy to manufacture. The water pressure, bending and flattening experiment is necessary and it requests the surface quality. The delivery length is usually 4-10m.

Transformer pipe: it is used in manufacturing of transformer radiator pipe and heat exchangers. And it is made by common carbon steel.

Wire casing: it is also called common carbon steel welding pipe. It is mainly used in concrete and various kinds of distribution project. Nominal diameter is from 13 to 76mm. Wire casing wall is much thinner, most of pipe need coating or galvanized. And it needs to do bending test.

Special pipe: it is mainly used for agricultural machinery parts and steel window door etc. It is welded square pipe, rectangular pipe, steel doors and windows with ordinary carbon structural steel and 16Mn steel strip.

Spiral welding pipe: low carbon structural steel or low alloy structural steel are rolled tube billet according to certain helix angle thus weld the pipe seam to make spiral welding pipe. It is mainly used in petroleum and natural gas conveying pipeline. Spiral welding pipe has one side welding and both sides welding.

Production method:

1. Process: ERW pipe, LSAW pipe, SSAW pipe and DSAW pipe.

2. Welding seam: straight seam welding pipe and spiral welding pipe

Applications

Welding pipe has a wide application in water project, petrochemical industry, chemical industry, power industry, agricultural irrigation and urban construction.

Specializing in various kinds of pipes production and supplying, Anson steel is a professional welding pipe manufacturer and supplier in the international trade. We keep enough in stock in the warehouse every month. Besides, Ourway steel keeps a good relationship with every big steel factory in China, so we can guarantee the delivery time and competitive prices for customers. Therefore, if you have any inquiry on welding pipe, please don‘t hesitate to contact us by e-mail or ring us!