API 5L line pipe

It is well-known that API 5L refers to API 5L line pipe, which is a international standard specifies requirements for manufacturing two products specification levels of seamless steel pipes and welded steel pipes for applications in oil pipeline transportation systems in the petroleum and natural gas industries. Two levels include PSL1 and PSL2. Additionally, the number of API 5L welded steel pipes is more than API 5L seamless steel pipes, due to lower cost.

Name: API SPEC 5L Line Pipe

Steel Grade:

PSL 1: A, B, x42, x46, x52, x56, x60, x65, x70;

PSL 2: B, x42, x46, x52, x56, x60, x65, x70, x80

Standard: API SPEC 5L

Applications: API SPEC 5L is widely used for oil and natural gas industry, gas, petroleum, water and oil transportation.

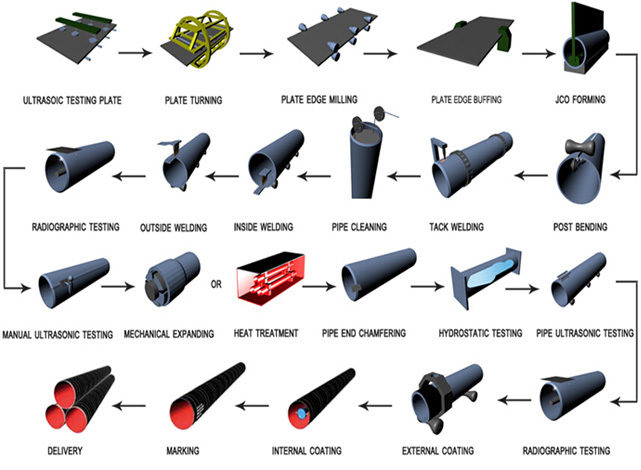

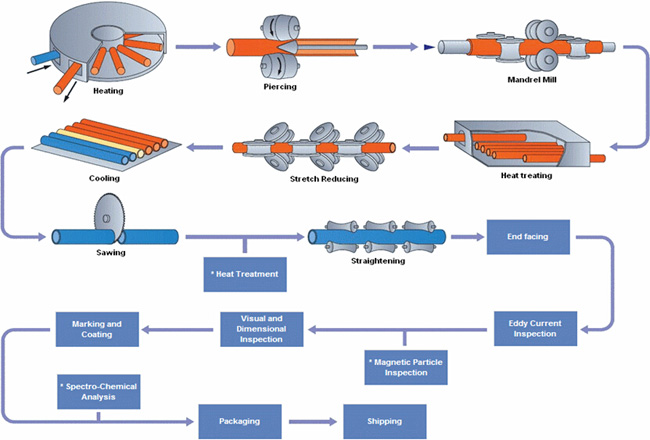

Different Technology API 5L Line Pipe: Seamless Line Pipe/ ERW Linepipe/LSAW Linepipe

Specializing in various kinds of API 5L line pipe production and supplying, Ourway steel subsidiary of AGICO is a professional OCTG manufacturer and supplier in the international trade. We keep enough in stock in the warehouse every month. Besides, we keep a good relationship with every big steel factory in China, so we can guarantee the delivery time and competitive prices for customers. Therefore, if you have any inquiry on API 5L, please don‘t hesitate to contact us by e-mail or ring us!

API 5L PSL 1 Chemical composition and mechanical properties:

|

Standard |

Steel grade |

Chemical Compositions(%) | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|

| C(max) | Mn(max) | P(max) | S(max) | Tensile strength(Mpa) | Yield strength(Mpa) | ||

| API SPEC 5L | B | 0.28 | 1.20 | 0.030 | 0.030 | 414 | 241 |

| X42 | 0.28 | 1.30 | 0.030 | 0.030 | 414 | 290 | |

| X46 | 0.28 | 1.40 | 0.030 | 0.030 | 434 | 317 | |

| X52 | 0.28 | 1.40 | 0.030 | 0.030 | 455 | 359 | |

| X56 | 0.28 | 1.40 | 0.030 | 0.030 | 490 | 386 | |

| X60 | 0.28 | 1.40 | 0.030 | 0.030 | 517 | 414 | |

| X65 | 0.28 | 1.40 | 0.030 | 0.030 | 531 | 448 | |

| X70 | 0.28 | 1.40 | 0.030 | 0.030 | 565 | 483 | |

API 5L PSL 2 Chemical Composition and Mechanical Properties:

|

Standard |

Steel grade |

Chemical Composition(%) | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|

| C(max) | Mn(max) | P(max) | S(max) | Tensile strength | Yield strength | ||

| API SPEC 5L | B | 0.24 | 1.20 | 0.025 | 0.015 | 414-758 | 241-758 |

| X42 | 0.24 | 1.30 | 0.025 | 0.015 | 414-758 | 290-758 | |

| X46 | 0.24 | 1.40 | 0.025 | 0.015 | 434-758 | 317-758 | |

| X52 | 0.24 | 1.40 | 0.025 | 0.015 | 455-758 | 359-758 | |

| X56 | 0.24 | 1.40 | 0.025 | 0.015 | 490-758 | 386-758 | |

| X60 | 0.24 | 1.40 | 0.025 | 0.015 | 517-758 | 414-758 | |

| X65 | 0.24 | 1.40 | 0.025 | 0.015 | 531-758 | 448-758 | |

| X70 | 0.24 | 1.40 | 0.025 | 0.015 | 565-758 | 483-758 | |

Specifications of API 5L Line Pipe

| Nominal Size | Outside Diameter | Wall Thickness | Plain-end Weight | |||

|---|---|---|---|---|---|---|

| inch | mm | inch | mm | lb/ft | kg/m | |

| 0.405 | 0.405 | 10.29 | 0.095 | 2.4 | 0.31 | 0.47 |

| 0.54 | 0.54 | 13.72 | 0.088 | 2.2 | 0.43 | 0.62 |

| 0.54 | 13.72 | 0.119 | 3.0 | 0.54 | 0.79 | |

| 0.675 | 0.675 | 17.15 | 0.091 | 2.3 | 0.57 | 0.84 |

| 0.675 | 17.15 | 0.126 | 3.2 | 0.74 | 1.10 | |

| 0.84 | 0.84 | 21.34 | 0.109 | 2.8 | 0.85 | 1.28 |

| 0.84 | 21.34 | 0.147 | 3.7 | 1.09 | 1.61 | |

| 1.05 | 1.05 | 26.67 | 0.113 | 2.9 | 1.13 | 1.70 |

| 1.05 | 26.67 | 0.154 | 3.9 | 1.48 | 2.19 | |

| 1.315 | 1.315 | 33.4 | 0.133 | 3.4 | 1.68 | 2.52 |

| 1.315 | 33.4 | 0.179 | 4.6 | 2.17 | 3.21 | |

| 1.660 | 1.660 | 42.2 | 0.145 | 3.7 | 2.72 | 3.43 |

| 1.660 | 42.2 | 0.191 | 4.9 | 3.00 | 4.51 | |

| 1.900 | 1.660 | 42.2 | 0.382 | 9.7 | 5.22 | 7.77 |

| 1.900 | 48.3 | 0.145 | 3.7 | 2.72 | 4.07 | |

| 1.900 | 48.3 | 0.200 | 5.1 | 3.63 | 5.43 | |

| 1.900 | 48.3 | 0.400 | 10.2 | 6.41 | 9.58 | |

| 2 3/8 | 2.375 | 60.3 | 0.109 | 2.8 | 2.64 | 3.97 |

| 2.375 | 60.3 | 0.125 | 3.2 | 3.00 | 4.51 | |

| 2.375 | 60.3 | 0.141 | 3.6 | 6.36 | 5.03 | |

| Nominal Size | Outside Diameter | Wall Thickness | Plain-end Weight | |||

|---|---|---|---|---|---|---|

| inch | mm | inch | mm | lb/ft | kg/m | |

| 2 3/8 | 2.375 | 60.3 | 0.154 | 3.9 | 3.65 | 5.42 |

| 2.375 | 60.3 | 0.172 | 4.4 | 4.05 | 6.07 | |

| 2.375 | 60.3 | 0.188 | 4.8 | 4.39 | 6.57 | |

| 2.375 | 60.3 | 0.218 | 5.5 | 5.02 | 7.43 | |

| 2.375 | 60.3 | 0.250 | 6.4 | 5.67 | 8.51 | |

| 2.375 | 60.3 | 0.281 | 7.1 | 6.28 | 9.31 | |

| 2.375 | 60.3 | 0.436 | 11.0 | 9.03 | 13.47 | |

| 2 7/8 | 2.875 | 73.0 | 0.109 | 2.8 | 3.22 | 4.85 |

| 2.875 | 73.0 | 0.125 | 3.2 | 3.67 | 5.51 | |

| 2.875 | 73.0 | 0.141 | 3.6 | 4.12 | 6.16 | |

| 2.875 | 73.0 | 0.156 | 4.0 | 4.53 | 6.81 | |

| 2.875 | 73.0 | 0.172 | 4.4 | 4.97 | 7.44 | |

| 2.875 | 73.0 | 0.188 | 4.8 | 5.40 | 8.07 | |

| 2.875 | 73.0 | 0.203 | 5.2 | 5.79 | 8.69 | |

| 2.875 | 73.0 | 0.216 | 5.5 | 6.13 | 9.16 | |

| 2.875 | 73.0 | 0.250 | 6.4 | 7.01 | 10.51 | |

| 2.875 | 73.0 | 0.276 | 7.0 | 7.66 | 11.39 | |

| 2.875 | 73.0 | 0.552 | 14.0 | 13.69 | 20.37 | |

| 3 1/2 | 3.5 | 88.9 | 0.141 | 3.6 | 5.06 | 7.57 |

| 3.5 | 88.9 | 0.156 | 4.0 | 5.57 | 8.37 | |

| 3.5 | 88.9 | 0.172 | 4.4 | 6.11 | 9.17 | |

| 3.5 | 88.9 | 0.188 | 4.8 | 6.65 | 9.95 | |

| 3.5 | 88.9 | 0.216 | 5.5 | 7.58 | 11.31 | |

| 3.5 | 88.9 | 0.250 | 6.4 | 8.68 | 13.02 | |

| 3.5 | 88.9 | 0.281 | 7.1 | 9.66 | 14.32 | |

| 3.5 | 88.9 | 0.300 | 7.6 | 10.25 | 15.24 | |

| 3.5 | 88.9 | 0.600 | 15.2 | 18.58 | 27.63 | |

| 4 | 4 | 101.6 | 0.156 | 4.0 | 6.40 | 9.63 |

| 4 | 101.6 | 0.172 | 4.4 | 7.03 | 10.55 | |

| 4 | 101.6 | 0.188 | 4.8 | 7.65 | 11.46 | |

| 4 | 101.6 | 0.226 | 5.7 | 9.11 | 13.48 | |

| 4 | 101.6 | 0.250 | 6.4 | 10.01 | 15.02 | |

| 4 | 101.6 | 0.281 | 7.1 | 11.16 | 16.55 | |

| 4 | 101.6 | 0.318 | 8.1 | 12.50 | 18.68 | |

| 4 1/2 | 4.5 | 114.3 | 0.156 | 4.0 | 7.24 | 10.88 |

| 4.5 | 114.3 | 0.172 | 4.4 | 7.96 | 11.92 | |

| 4.5 | 114.3 | 0.188 | 4.8 | 8.67 | 12.96 | |

| 4.5 | 114.3 | 0.203 | 5.2 | 9.32 | 13.99 | |

| 4.5 | 114.3 | 0.219 | 5.6 | 10.02 | 15.01 | |

| 4.5 | 114.3 | 0.237 | 6.0 | 10.80 | 16.02 | |

| 4.5 | 114.3 | 0.250 | 6.4 | 11.36 | 17.03 | |

| 4.5 | 114.3 | 0.281 | 7.1 | 12.67 | 18.77 | |