casing pipe

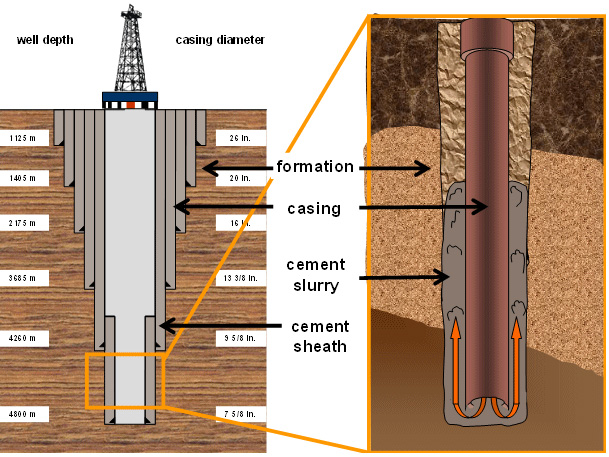

Casing pipe is the pipe, which is used to support the oil and gas well wall, in order to ensure that the drilling process and the normal running of the whole well after completion. According to different drilling depth and geological condition, every well uses several layers of casing. Casing is different from tubing and drill pipe after using. Casing is the one-time consumption materials and can’t be repeated use. So the consumption of casing is accounted for more than 70% of the total oil well pipe. Casing is the oil special pipe which is mainly used in oil and gas well drilling and oil and gas transportation. Casing includes petroleum drill pipe, oil casing and oil-well tubing. Petroleum drill pipe is mainly used to connect the drill collar and drill at the same time transmits drilling power. Oil-well tubing mainly transfers the bottom of the oil and gas to the ground.

Name: Casing Pipe

Steel Grade: J55, K55, N80, L80, C90, T95, P110, Q125, V150

Standard: API SPEC 5CT

Specifications:

Out Diameter: 4 1/2"- 20" (114.3mm-508mm)

Wall Thickness: 0. 205"- 0.635"

Length: R1(4.88mtr-7.62mtr), R2(7.62mtr-10.36mtr), R3(10.36mtr or longer)

Applications: Oil casing is a kind of large diameter pipes and play an important role to fix oil and gas well wall and well hole. Casing is inserted into the well hole and fixed with cement in order to prevent the borehole and separated strata borehole collapse and ensure drilling mud circulating flow and drilling.

Steel casing pipe is lifeline to maintain oil wells running. Due to different geological conditions, underground stress state is complex like tension, pressure, bending, and torsion stress to require the casing with higher quality. Once the casing is damaged due to some reasons, which will lead to the whole production of the well or even scrapped. According to steel strength, casing can be divided into different steel grades: J55、K55、N80、L80、C90、T95、P110、Q125、V150 etc. The steel grade is in different way due to different oil well conditions and depth. In corrosive environment, casing is required to have good corrosion resistance.

What is the Material of the Oil Casing?

27MnCrV is the new steel grade to produce TP110T steel grade oil casing pipeline. The common steel grade is 29CrMo44 and 26CrMo4. Compared to 29CrMo44 and 26CrMo4, 27MnCrV contains less Mo elements, which can greatly reduce the production cost. Subcritical quenching is the technology during the process of oil casing. This technology can reduce the quenching stress, thus reducing the quenching deformation so as to ensure the smooth operation of heat treatment production and provide goof raw material for subsequent processing. After heat treatment, yield strength Rt0.6 is 820-860MPa; tensile strength Rm is 910-940MPa; impact toughness Akv is 65-85J and anti-destruction performance is 100% qualified. Data show that 27MnCrV steel is quite high quality grade oil casing.

Surface oil casing: it protects the drilling and makes the well avoid polluting by shallow water layer and shallow gas pay; besides, it supports the well head equipment and keep other layer weight of the casing.

Technology oil casing: it separates different levels of pressure so as to normal circulation and protects the production casing. In addition, in order to install the blowout drilling device, suppressor and tail pipe in the drilling well.

Oil reservoir oil casing: it derived the oil and natural gas from the storage layer under the surface of the earth. And it is also used to protect drilling and layer the drilling mud.

During the casing production, the outer diameter is usually 114.3mm to 508mm.

2.For the new production of injection wells, adopt adding the sterilization of annulus protection fluid and form system to dose regularly.

3.In view of mechanical abrasion will accelerate oil casing corrosion, it suggests that tubing coupling adds a rubber ring or a centralizer in serious deviation part to avoid in the process of operation and water injection tubing scratch on one side and touch casing pipe.

4.Don’t recommend to adopt cathodic protection and coating casing before injection well casing corrosion getting effective control.

Packing

Casing is strapped with steel wire and steel strip. Each casing and coupling thread showing parts should be screwed on protection ring to protect the threads.

Casing Pipe Specifications:

| Steel Grade | OD(mm) | Weight | Wall Thickness(mm) | Inner Diameter(mm) | Length(m) |

|---|---|---|---|---|---|

| j55/n80/p110 | 139.7(5-1/2) |

20.85(0.244) 23.09(15.50) 25.32(17.00) 29.79(20.00) 34.26(23.00) |

6.20(0.244) 6.98(0.275) 7.72(0.304) 9.17(0.361) 10.54(0.415) |

127.3(5.012) 125.7(4.950) 124.3(4.892) 121.4(4.778) 118.6(4.670) |

8m-12m (2602-39.4) |

| j55/n80/p110 | 177.8(7) |

25.529(17.00) 29.79(20.00) 34.26(23.00) 38.73(26.00) 43.20(29.00) 47.66(32.00) 52.13(35.00) 56.60(38.00) |

5.87(0.231) 6.91(0.272) 8.05(0.317) 9.19(0.362) 10.36(0.408) 11.51(0.453) 12.65(0.498) 13.72(0.540) |

166.1(6.538) 164.2(6.456) 161.7(6.366) 159.4(6.276) 157.1(6.180) 154.8(6.090) 152.5(6.004) 150.4(5.430) |

8m-12m (2602-39.4) |

| j55/n80/p110 | 219.1(8-5/8) |

35.75(24.00) 41.71(28.00) 47.66(32.00) 53.62(36.00) 59.58(40.00) |

6.71(0.264) 7.72(0.304) 8.94(0.352) 10.16(0.400) 11.43(0.450) |

205.7(8.093) 203.7(8.020) 201.2(7.927) 198.8(7.827) 196.2(7.724) |

8m-12m (2602-39.4) |

| j55/n80/p110 | 244.5(9-5/8) |

48.11(32.30) 53.62(36.00) 59.58(40.00) 64.79(43.50) 70.01(47.00) 71.69(53.50) |

7.92(0.312) 8.94(0.352) 10.03(0.395) 11.05(0.435) 11.99(0.472) 13.84(0.545) |

228.7(9.001) 226.6(8.921) 224.4(8.835) 222.4(8.755) 220.5(8.681) 216.8(8.535) |

8m-12m (2602-39.4) |

| j55/n80/p110 | 273.0(10-3/4) |

48.78(32.75) 60.32(40.50) 67.77(45.50) 75.96(51.00) 82.67(55.50) |

7.09(0.279) 8.89(0.350) 10.26(0.400) 11.43(0.450) 12.57(0.495) |

258.9(10.192) 255.3(10.050) 252.7(9.950) 250.2(9.850) 247.9(9.760) |

8m-12m (2602-39.4) |

| j55/n80/p110 | 339.7(13-3/8) |

71.50(48.00) 81.18(54.50) 90.86(61.00) 101.69(68.00) |

8.38(0.330) 9.65(0.380) 10.92(0.430) 12.19(0.480) |

322.9(12.715) 320.4(12.615) 317.9(12.515) 315.3(12.415) |

8m-12m (2602-39.4) |

| j55/n80 | 73.0(2-7/8) |

9.53(6.40) 11.62(7.90) 12.81(8.60) |

5.51(0217) 7.01(0.276) 7.82(0.308) |

62.00(2.441) 59.00(2.323) 57.40(2.259) |

8.5m-9.5m (27.9-31.2) |

| j55/n80 | 88.9(3-1/2) |

11.47(7.70) 15.19(10.20) |

5.49(0.216) 7.34(0.289) |

77.9(3.067) 76.0(2.992) |

8.5m-9.5m (27.9-31.2) |

| j55/n80 | 114.3(4-1/2) | 18.77(12.60) | 6.88(0.271) | 100.5(3.957) |

8.5m-9.5m (27.9-31.2) |

Mechanical Properties:

| Grade | Type | Total elongation under load (%) | Yield strength (min) | Yield strength (max) | Tensile strength min Mpa | Hardness Max (HRC) | Hardness Max (HBW) |

|---|---|---|---|---|---|---|---|

| J55 | - | 0.5 | 379 | 552 | 517 | ||

| K55 | - | 0.5 | 379 | 552 | 655 | ||

| N80 | 1 | 0.5 | 552 | 758 | 689 | ||

| N80 | Q | 0.5 | 552 | 758 | 689 | ||

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | ||

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | ||

| Q125 | All | 0.65 | 862 | 1034 | 931 |

Specializing in various kinds of OCTG pipes production and supplying, Ourway steel is a professional tubing and casing manufacturer and supplier in the international trade. We keep enough in stock in the warehouse every month. Besides, Ourway steel keeps a good relationship with every big steel factory in China, so we can guarantee the delivery time and competitive prices for customers. Therefore, if you have any inquiry on tubing and casing, please don‘t hesitate to contact us by e-mail or ring us!