why choose welding steel pipe

Welding steel pipe is a kind of pipe that has the steel pipe joint on the surface. The welding steel tubing is use the steel belt or steel plate material through the bending deformation into round, square round then welded into shape. Why choose welding steel pipe for the project? Today, Anson Steel, as a welded steel tube supplier, will tell you the reasons.

The tube is manufactured without seam to make better pipe carry petrol oil, natural gas, water and other fluids. The black steel pipe is also applied for fire sprinkler systems because it is more resistant than the galvanized pipe.

Welding steel tube are widely used in boilers, pipeline, automobiles, ship building lightweight structural steel of the doors and windows, furniture, agricultural machinery, scaffolding, wire conduit, top shelves, containers etc. Therefore, welded steel tubing can meet different requirements of customers. Furthermore, the special specifications welded pipe can be processed depending on the customers’ demands. Welded steel tube also can applied in conveying water, sewage, gas, heating, steam and other low pressure fluid etc. Above all, the cost of welding steel pipe is much more cheaper than seamless steel pipe. Therefore, the welded steel tube is popular in recent years in the market.

According to different welding methods, welded steel tube can be divided into electric arc welding tube, the high frequency or low frequency electric resistance welded pipe and gas welding tube as well as furnace welding pipe etc.

ERW: Electric resistance welded steel tube is mainly used in oil drilling and machinery manufacturing etc.

LSAW: Longitudinal submerge arc welded steel tube is mainly used for high pressure straight oil and gas transportation etc.

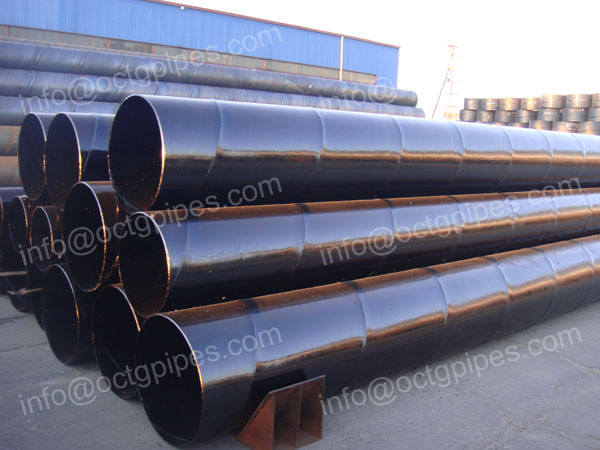

SSAW: Spiral welded steel tube is mainly used for the oil and natural gas transmission and pipe pile etc.

Pipe coating: HDPE/ 3PE/ 3PP/ Pipe cement mortar lining;

Get In Touch