differences of seamless steel tube and welded steel pipe

Steel pipe, as an important part of iron and steel products, because of its manufacturing process and tube billet shape in different way, is divided into welded steel pipe and seamless steel tube. While engineering construction rarely uses seamless steel pipe, welded steel pipe is very popular. Scaffolding steel pipe is a kind of straight seam welded pipe.

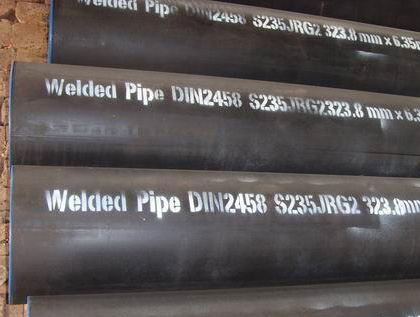

Welded Steel Pipe

Welded steel pipe adopts steel plate or steel strip as billet, because of different welding process, welded pipe is divided into furnace welded pipe, ERW tube and automatic arc welding tube. Because of different welding form, welded steel pipe is divided into straight seam welded pipe and spiral welded pipe. Due to material and application in different way, classification is as follows:

Low pressure fluid conveying welded steel pipe: Material is Q235A; it is mainly used to convey water, gas, air, oil and heating hot water or steam etc.

Mechanical stainless welded steel pipe: Material is 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb; it is mainly applied in machinery, automobile, bicycle, furniture and other mechanical parts and components.

Fluid conveying stainless welded steel pipe: Material is 0Cr13, 0Cr19Ni9, 00Cr19Ni11, 00Cr17, 0Cr18Ni11Nb; it is mainly used to convey low pressure corrosive medium.

Seamless steel tube

Due to different manufacturing process, seamless steel tube is divided into hot rolling and cold drawing seamless steel tubes.

API SPCE 5CT: it is American Petroleum Institute for casing and tubing. Casing: the main material is J55, N80, P110 (J55 and N80 can be welded steel pipe.) Tubing: the main material is J55, N80, P110, C90 and T95.

API 5L: the main material is B, X42, X56, X65, X70 etc.

ASTM A106: It is mainly used to convey fluid, general structure and mechanical structure.

ASTM SA213: it is mainly used to high pressure boiler, power station and high pressure pipeline.