seamless steel tube production process

Seamless steel tube has been known as a construction material. But few persons know the seamless steel tube production process. According to production process, seamless steel pipes can be divided into hot rolled seamless steel pipe and cold drawn seamless steel tube. Today Anson Steel, as a professional seamless steel pipe manufacturer, will introduce some production processes to help you how to select seamless steel pipes.Hot Rolled Seamless Steel Pipe

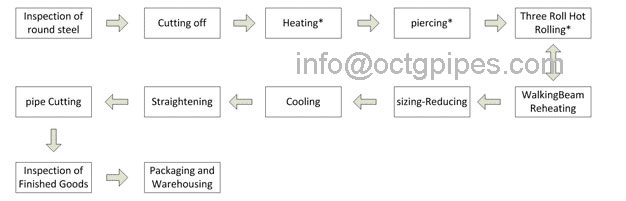

Hot-rolled seamless steel pipe is generally produced on automatic tube rolling machine. Solid billet is cleared the surface defects through inspection and then cut into the required length. Solid billet is centered on the tube billet perforation end face. Then the billet is sent to a heating furnace and punched on the punch. During the perforated, the billet revolves and progresses continuously, under the role of rolling roller and top, the internal cavity of pipe billet is formed gradually, which is called hollow billet. The furnace temperature control is critical to wear air round tube. Generally, the common puncher is tapered roller punch with high production efficiency, high quality, perforated expanding volume and wearing a variety of steels. The hollow billet is continued to roll on automatic tube rolling machine. Finally, the billet is reeled the whole wall thickness by reeling mill and sized by sizing machine to meet the specification requirements. It is an efficient method to improve the quality of hot rolled seamless steel tube.

The Production Process of Hot Rolled Seamless Steel Pipe

Cold Drawn Seamless Steel Tube

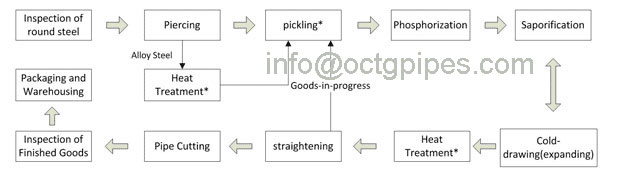

If you want to get a smaller size and better quality seamless steel pipe, you must adopt the cold rolling, cold drawing or both combined. The basic first to three production process is the same. The cold rolling is usually process in the second mill. That is to say, the difference from the fourth step, the circular tube was empty to begin annealing. Pickling need a special acidic liquid after annealing and oiling. Through multi pass cold drawn, blank tube is finished and then enter into specialized heat treatment system. Straightening is necessary. The steel pipe is rolled in the annular groove which is made with variable cross section round holes groove and motionless conical head. Cold drawing is usually processed in single or double chain cold drawn machine of 0.5~100T. In the interior of pipes, some quality defects like cracks and bubbles will be checked. The quality inspection for cold drawn seamless steel tube is also by a rigorous manual selection.

The Production Process of Cold Drawn Seamless Steel Tube

Extrusion Method

Extrusion method is that the heating tube billet is put into airtight extrusion cylinder, and perforated rods with extrusion stem are moving that make extrusion pressed from the smaller die. This method is suitable for producing smaller diameter seamless steel pipe which is a hollow section without seams of strip steel.

Get In Touch