issues on ERW pipe welded joints

ERW pipe welded joints the most important advantages are no ERW welded filler metal, heating speed and high production efficiency. Of course, there are some shortcomings. No welded filler metal can’t benefit approach elements improve welded properties; heating temperature is very high, when the sound is more short, the welded temperature gradient is more greater, so that, certain steel grades are prone to hardening phase stress, the welding fragility and comprehensive mechanical performance in the welding process. Therefore, it needs to post welded seam ERW remedies, and welded heat treatment can eliminate stress, improve the organization and performance of ERW pipes.

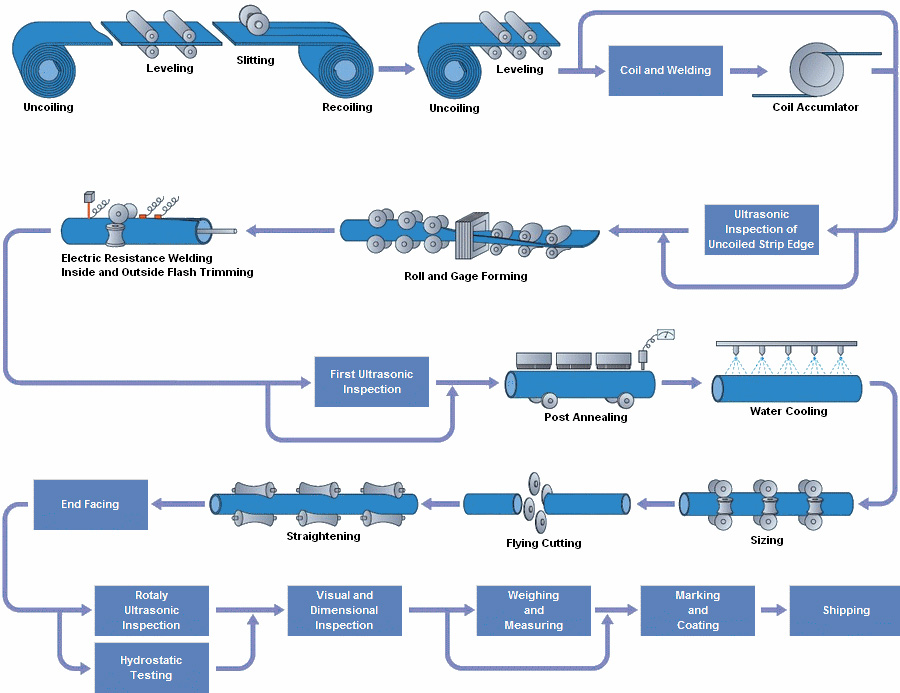

ERW Pipe Process:

In recent years, with the development of cold regions heating supply and marine fields, ERW steel pipes have a great broad prospect in lots of national projects. Meanwhile this requires ERW pipes with good low temperatures and corrosion resistance to adapt the local climate environment. But now, many ERW pipe manufacturers welds poor low temperature toughness and high values, which greatly limit ERW pipes development and scope. The technology of ERW steel pipe welded low temperature toughness has become such an important indicator in this level.

Heating is usually induction heating for welded line heat treatment process; in order to ensure the welded heat sensor accuracy, adopting advanced automatic welding unit equipped with photoelectric tracking system; furthermore, to ensure heating temperature stability, it is equipped with automatic temperature control systems; heat treat process types mostly use normalizing welded. In welded annealing process, some ERW pipe manufacturers are to improve the welded toughness and high strength steel using the heat treatment process transfer. And the quenching process welded grain has been refined to improve the toughness of the welded.